SIG P320 RX Series / Pro Series / AXG Scorpion w/ R1P / DPP CUT w/ RMR / Holosun Holes – Filler Plate for Trijicon RMR / SRO / RCR / Holosun 407C / 507C / 507Comp / 508T / C&H EDC-XL / COMP

$60.45

THE MOST MODULAR, RUGGED, DURABLE, RELIABLE AND MOST WIDELY USED AFTERMARKET OPTICS ADAPTER PLATE.

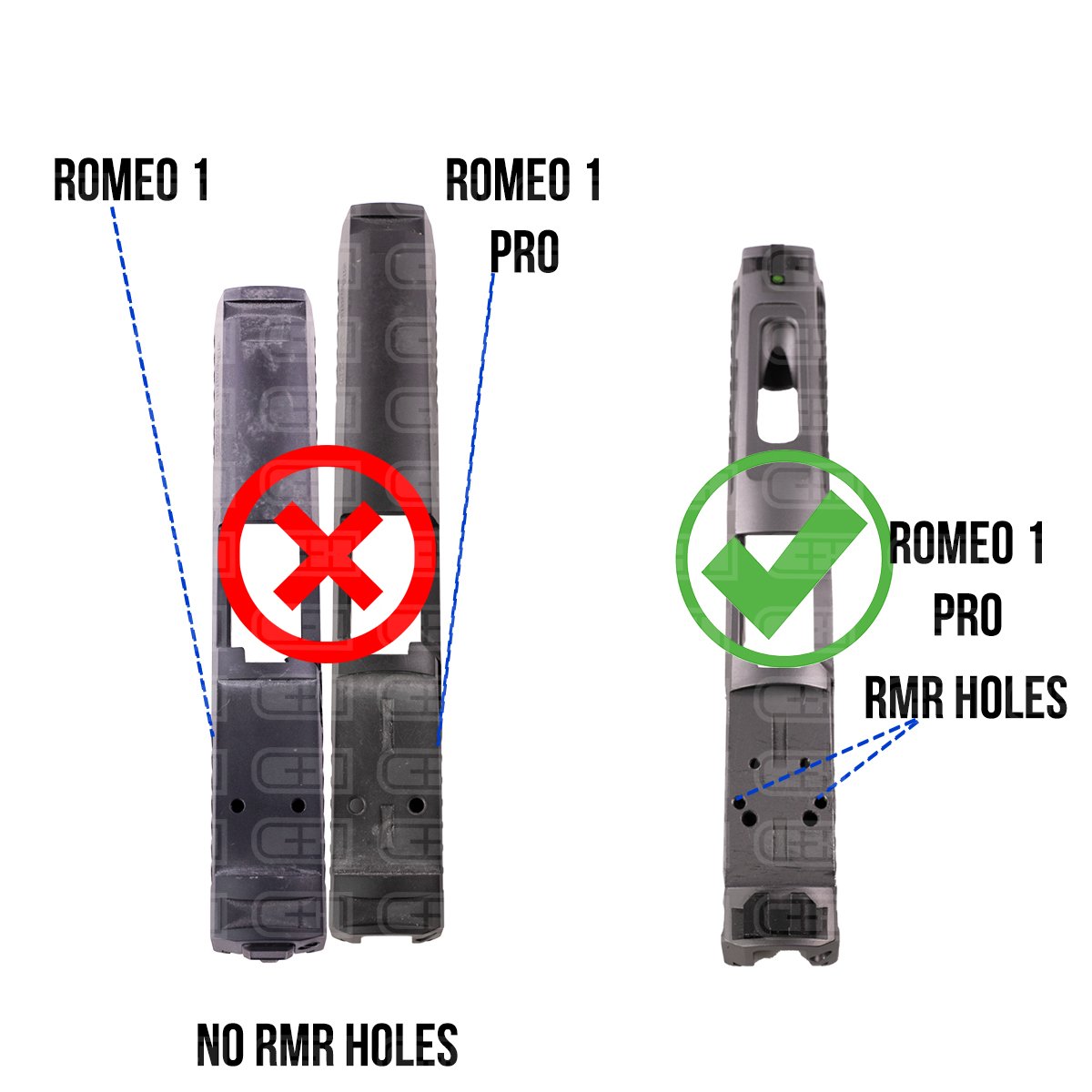

THIS PLATE REQUIRES A ROMEO 1 PRO OPTIC READY CUT WITH RMR HOLES, REFER TO THE PICTURES TO VERIFY YOUR SLIDE HAS THE CORRECT HOLES AND CUT. IF YOUR SLIDE DOES NOT HAVE RMR / HOLOSUN THREADED HOLES OR NEEDS TO BE UPGRADED TO THE ROMEO 1 PRO CUT, CLICK HERE

**FOR TRIJICON RCR, READ THE DESCRIPTION BELOW**

**This plate is for slides that DO NOT LOSE the rear iron sight when the cover plate is removed**

DIRECT MILL YOUR OPTIC CLICK HERE

Out of stock

Want to be notified when this product is back in stock?

This filler plate does not require any additional screws. It is held in place with the RDS and it’s mounting screws.

The C&H Precision plates are designed, manufactured and shipped from our small family owned business in Coastal Georgia. Each plate is precision machined to the tightest tolerances on HAAS CNC machines and each plate goes through multiple quality checks before shipping to our customers.

SPECIFICATION:

Material: Plates are made from 6061 aluminum. All mounting hardware is Stainless Steel

Finish: Plates are MIL-SPEC Type III Hard Anodized – Black

INCLUDED:

Qty 1 – Optic Plate

Qty 3 – 6-40 x .380 M3H Trijicon RMR / RMR HD / SRO , Holosun 507C / 508T Optic Mounting Screws

Qty 3 – 6-40 x .460 M3H CHPWS COMP / EDC XL Optic Mounting Screws

**Trijicon RCR**

The RCR Optic comes with Trijicon screws that are “Patented”. You must use the screws they provide you. C&H will not make new screws for this optic / plate combo. It is the responsibly of the consumer to check fitment of the provided screws for length. The screws may have to be slightly modified or shortened in order to ensure proper fitment.

Agency / Department Discount Program

Additional information

| Weight | .3 lbs |

|---|---|

| MANUFACTURER | |

| MODEL | P320 X SERIES (X-FIVE, X-COMPACT, X-CARRY) (Loses Rear Sight), P320-XTEN (Keeps Rear Sight) |

| RED DOT | HOLOSUN 407C / 507C / 508T, TRIJICON RMR, TRIJICON SRO, C&H COMP, C&H EDC XL, HOLOSUN 507Comp, Trijicon RCR |

68 reviews for SIG P320 RX Series / Pro Series / AXG Scorpion w/ R1P / DPP CUT w/ RMR / Holosun Holes – Filler Plate for Trijicon RMR / SRO / RCR / Holosun 407C / 507C / 507Comp / 508T / C&H EDC-XL / COMP

Only logged in customers who have purchased this product may leave a review.

Anthony Cefalu (verified owner) –

Outstanding service. They responded quickly to my inquiries as to the proper plate for my pistol. Prompt receipt of item. Would do business with them again for sure. Tony C.

glenn-55 (verified owner) –

Excellent adapter plate for my Holosun HS407C-X2 mounted on my Sig P320 AXG. Adapter fit perfectly and the Holosun mounted flawlessly. Very easy to install. I like to use a dab of Locktite 243 then wait 24 hrs before shooting. Nice price for this adapter with fast shipping from C&H. Highly recommended.

rodgersfrank71 (verified owner) –

For the Holosun 507 comp everything fit mounting it on the sig 320 x compact. However ….. the screws shipped did not fit. Too long. So I took some of the shorter screws shipped with the Holosun. They are actually too short…. But I righted them and used blue lock tight and will check for movement over time. It seems like with all the sigs you must see over time, you could match your screws perfectly. I will be reluctant to order future products because of that. Hopefullly you can resolved those quality issues in the future.

C&H Precision –

Thank you for taking the time to leave us a review, we take every experience our customers have seriously. Can you please reach out to us on our contact portal so we can get a little more information? This way we can determine what adjustments might need to be made so this kind of think does not happen again.

Ian Jarrell

Customer Service Manager

C&H Precision, LLC